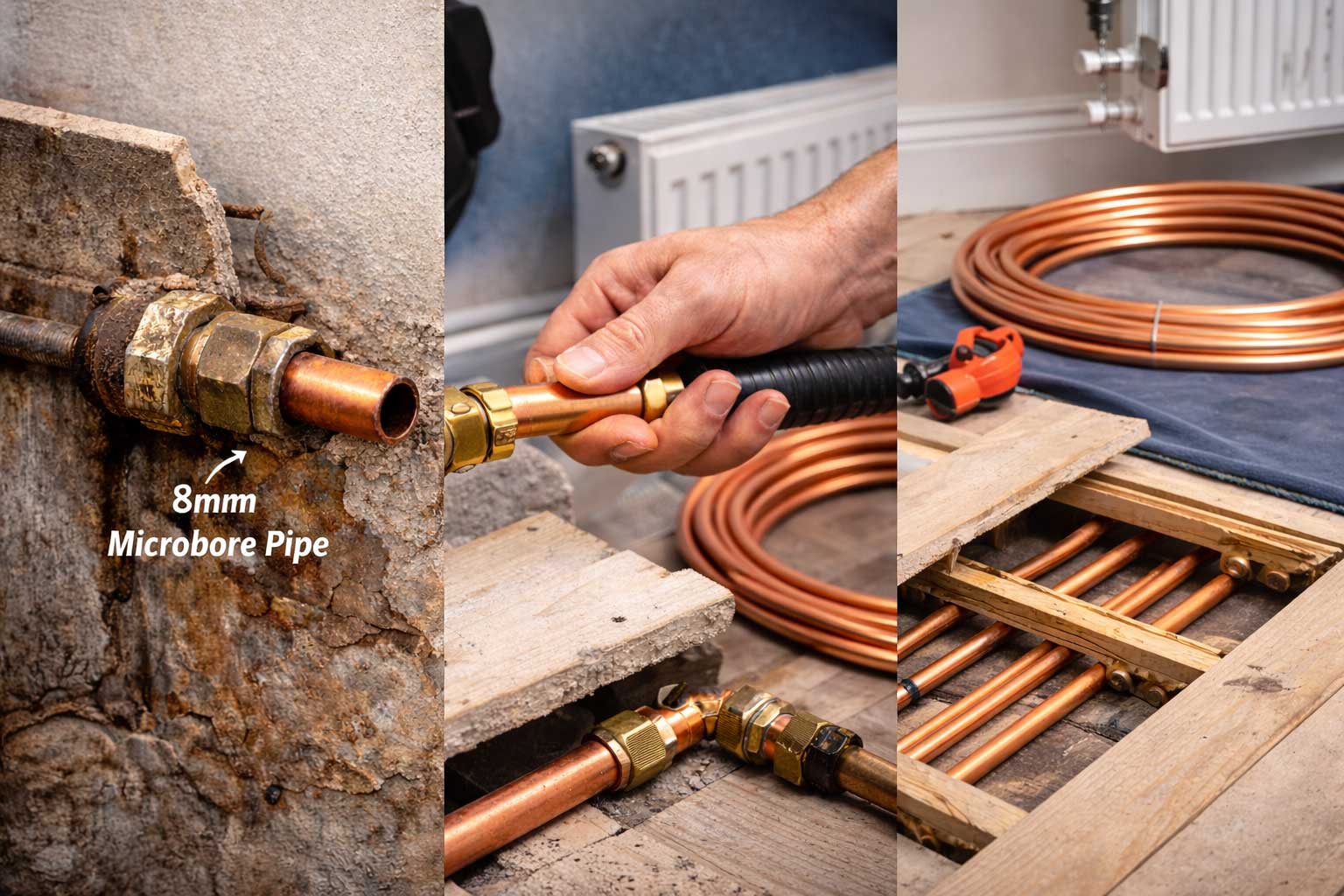

How Much Does Microbore Pipe Replacement Cost in Dublin?

Microbore Pipe Replacement Dublin – Microbore replacement usually isn’t the first thing homeowners look at.

It tends to come up after everything else has already been tried.

The boiler’s been serviced.

The system has been flushed.

Valves changed. Pump upgraded. Balancing done again… and again.

The building maintains its outdated design in particular areas. The cooling process of radiators occurs at a speed that exceeds their normal operation time. The system never quite settles.

The final cost calculation removes microbore pipework from the calculation to show the full extent of this major decision.

In most Irish homes, full microbore pipe replacement starts from around €8,000. The process involves removing all restricted pipework from service to install proper copper piping which enables water flow through the system.

The price of pipes changes because of factors which do not include the actual pipes.

Why House Layout and Radiator Numbers Matter

House layout matters more. The management of floor runs becomes simpler when dealing with basic floor designs instead of houses which have undergone multiple extensions and modifications throughout their history. Systems which start with basic elements need to operate for extended periods before they can achieve their optimal organisational state.

The numbers on radiators also need to be considered. The system requires special care because microbore systems will not tolerate any form of imbalance. Once new pipework goes in, everything has to be sized and set up as a complete system, not as a collection of fixes.

Why a Power Flush Is Not Required

One thing that often catches people out: there’s no need for a power flush. Once microbore pipework is disconnected, it’s no longer part of the circuit. The new pipework starts with a completely empty condition. There’s nothing left to clear out.

People tend to notice everyday objects only after an event occurs instead of paying attention to anything unusual.

It’s quieter than that.

The heating system in the rooms operates at times when it should not. Radiators stay balanced. The boiler stops overworking itself. The system behaves the same way from one week to the next.

For many households, the cost only makes sense when compared with what’s already been spent trying to keep an ageing system alive. The system requires replacement instead of an upgrade at this stage. The process reaches its final stage at this point.

Image credit: heatfromair.co.uk

Why Microbore Pipework Causes Ongoing Heating Problems

Designed for Smaller Systems and Lower Demand

The heating system in Irish homes operates beyond the original design parameters of microbore pipework.

The system became available to organisations when it launched as their initial business entry point for organisations that operated with limited capacity and served small numbers of customers. Fewer radiators. Shorter pipe runs. Lower expectations.

Where Flow Restriction Becomes the Bottleneck

Microbore pipes have a much smaller internal diameter than standard copper pipework. The system has a limited capacity to transport water because of this restriction. When demand increases — more radiators calling for heat, thermostatic valves opening and closing, modern boilers ramping up output — the pipework becomes the bottleneck.

The system functions through an endless battle which exists between its internal elements.

The distant radiators experience difficulty when hot water attempts to reach them. Rooms heat unevenly. The temperature measurements from different parts of the world demonstrate quick temperature increases, but specific areas maintain their cold climate, while others experience sudden drops in temperature. The process of balancing becomes challenging to maintain after performing it properly.

Why Pumps and Boilers Can’t Compensate

Pumps are often upgraded in an attempt to compensate. The solution provides short-term relief, but it creates additional system problems and equipment destruction, which do not resolve the fundamental issue. The water needs to travel through the same restricted pipe system.

Boilers experience the effects of this situation. The modern boiler system features smooth modulation and response capabilities; however, it will cycle repeatedly due to restricted water flow. The boiler operates in a cycle of shutdowns and restarts because it lacks sufficient heat transfer efficiency.

The random behaviour of microbore systems emerges because their operations follow no discernible pattern. The children maintain acceptable behaviour during the first week of the program. The following week brought back all previous problems when temperatures dropped.

No amount of servicing can change the physical limits of the pipework. The system develops structural problems because microbore pipes fail to provide sufficient supply to meet continuous demand at any time.

Common Signs Microbore Pipework Is Holding Your System Back

Microbore pipework rarely fails all at once. Instead, it creates a pattern of small, persistent problems that never quite go away.

The following list presents common indicators which show that your system faces performance limitations because of microbore pipework.

Uneven Heating and Cold Radiators

The entire system of microbore pipework will not experience a complete failure at any time. The system generates ongoing minor issues which continue to exist without resolution.

One of the most common signs of a heating system problem is uneven heat distribution throughout the home. Radiators closest to the boiler heat up quickly, while those further away struggle to reach the proper temperature or cool down faster than they should. This imbalance often persists even after attempting to balance the system.

Constant Adjustments and Poor Control

Another telltale sign is the need for constant adjustments. Homeowners find themselves repeatedly opening and closing thermostatic radiator valves, trying to achieve comfortable temperatures in different rooms. The system might respond temporarily, but it soon reverts to the same uneven heating pattern.

Noise, Strain and Rising Energy Use

Noise is also a frequent complaint. The pumps begin to produce humming and whining noises because they must overcome opposing forces to operate. The system produces rushed and strained pipe sounds when it starts operating, especially during peak demand periods of cold winter mornings.

Your heating system may exhibit several warning signs that suggest underlying issues with the pipework.

The boiler runs for longer periods to heat your home to a comfortable temperature. You might find yourself avoiding certain rooms during winter because they simply don’t warm up properly. Your energy bills show unexplained increases that can’t be attributed to usage changes or tariff adjustments.

When Symptoms Point to a Structural Limitation

While each of these symptoms alone might seem minor, together they paint a clear picture: your microbore heating system has reached its physical limitations. The narrow pipe diameter creates a fundamental restriction that can’t be overcome through repairs or adjustments alone. Unlike other heating problems that can be fixed with balancing or component replacement, this is an inherent design constraint of the system itself.

Why Individual Fixes Don’t Solve Microbore Problems

A radiator is swapped. A valve is replaced. A stronger pump is fitted. The individual changes appear reasonable when analysed independently from other modifications. The operational restriction which exists in theory continues to affect real-world operations.

Microbore Pipework Creates System-Wide Flow Restriction

The Microbore pipework system restricts fluid movement throughout the complete network instead of creating a single point of restriction. The process of replacing single parts leads to new system problems instead of solving the original issue. The condition of one space shows improvement, yet the other space experiences deterioration. The system needs to make continuous adjustments because its equilibrium target keeps shifting at all times.

Why Partial Pipe Upgrades Make Systems Harder to Control

The system will experience unbalanced operation because of the partial pipe upgrade installation. The change between large pipes and tiny microbore sections produces abrupt shifts between fluid pressure and speed. Water starts to move at increasing speed before it reaches a point where it becomes blocked. Noise increases. Control becomes less predictable.

Pump Upgrades: Short-Term Relief, Long-Term Damage

The process of upgrading pumps serves as a typical example. The pump output increase will create a short-term water flow through restricted pipework, but it will also speed up the deterioration of equipment. Bearings fail sooner. Noise levels rise. The system becomes more difficult to manage when the weather conditions are not extreme.

Why Boilers Get Blamed When the Pipework Is the Limitation

People tend to criticise boilers the most. Modern appliances are installed with higher efficiency expectations, yet they are still reliant on the same restricted distribution network. The boiler system has received a new installation, but it continues to operate under the same performance constraints which existed before.

The Hidden Cost of Repeated Micro-Fixes

The multiple solutions which have been added will eventually require more money than what was initially predicted. The doctor treats a different symptom during each office appointment. None of these solutions identifies the root problem.

When Full Replacement Becomes the Only Stable Option

The reliability of microbore pipework systems will not be enhanced until the system restriction is eliminated at this point. The system requires full replacement because it enables designers to create an entire system from scratch instead of making incremental improvements to its most vulnerable sections.

What’s Involved in Replacing Microbore Pipework in Irish Homes

Microbore pipe replacement is a structured process rather than a disruptive free-for-all. The organisation seeks to eliminate all limitations while creating an integrated system which operates as a unified entity.

The first requirement involves following the current paths which the pipes currently follow. Microbore pipes run through various areas of homes because they are installed under floor spaces and they pass through stud walls and extend to new additions which were built during different time periods. The planning of replacement operations depends on the layout,

Image credit: https://www.reddit.com/r/DIYUK/comments/1hzt0ql/leaking_microbore_joint/

which serves as the determining factor.

Once identified, the microbore pipework is fully decommissioned. It is isolated and removed from service so it no longer forms part of the heating circuit.

The installation of new copper pipework follows after which the system receives its correct piping dimensions based on the number of radiators and total pipe distance and boiler power output. Radiators and valves are replaced where required so the system is balanced from the outset rather than adjusted repeatedly afterwards.

The system requires installation before personnel can perform filling operations and check the system and complete the commissioning process to verify proper fluid movement and operational stability.

How Long Does Microbore Pipe Replacement Take?

The duration of Irish home maintenance depends on the property design and its accessibility but most properties require maintenance within a standard time period.

The process of verifying basic properties and small properties requires two to three days for completion. The duration of the assessment depends on the number of extensions in the home as well as the complexity of its floor design and the total number of radiators.

The primary goal involves reaching maximum speed instead of performing tasks at a fast pace without any direction. The system will operate at a stable performance level after project completion because of proper routing methods and secure fixing techniques and complete commissioning procedures.

Should Microbore Pipework Be Replaced All at Once?

The duration needed for heating system maintenance or upgrade work depends on your home size and layout and its accessibility but most Irish houses need maintenance within a standard time period.

For standard two to three-bedroom homes, the work typically takes two to three days to complete. The duration of the work will increase when dealing with properties that have extensions and complex floor plans and multiple radiators.

The main requirement demands that you finish your work by doing it correctly rather than working at a fast pace. A properly executed installation which includes strategic pipe placement and solid mounting systems and complete system testing will provide your heating system with dependable and efficient operation throughout its entire operational period.

Safety and Performance Risks of Leaving Microbore Pipework in Place

The use of microbore pipework systems does not result in immediate safety failures, but it creates continuous safety threats because of its tendency to stretch and its poor operational efficiency.

The boiler needs to operate at higher frequencies because restricted water flow requires pumps to operate more frequently, which leads to shorter system component lifespans. The continuous operation of equipment will eventually cause equipment failures, which produce unexpected system failures.

The hidden nature of this problem inside the pipework system makes it continue to exist after multiple service operations and replacement of parts.

Getting a Quote for Microbore Pipe Replacement

Quoting for microbore replacement begins with understanding how the existing system is laid out and how the home is used day to day.

An assessment looks at pipe routes, radiator locations, boiler capacity, and access points. From there, replacement options can be mapped clearly, with realistic timelines and transparent pricing.

Clear planning at this stage prevents surprises later and ensures the finished system performs as intended.

Frequently Asked Questions

Is microbore pipework always a problem?

Not immediately. Issues usually develop as systems grow or heating demand increases beyond what the pipe size can support.

Can flushing or balancing fix microbore issues?

These measures can improve performance temporarily, but they cannot overcome the physical restriction of the pipe diameter.

Does microbore replacement require a power flush?

No. Once microbore pipework is removed from service, the new system starts clean and unrestricted.

Will floors or walls need to be opened?

Access is required in certain areas, but work is planned to minimise disruption wherever possible.

Is it worth replacing microbore pipework?

For homes experiencing repeated imbalance, poor circulation, or rising running costs, replacement often marks the point where problems stop recurring.

Low Water Pressure in Your House?….Read our blog post for full details